Container Gassing Prevents Pest Infestation

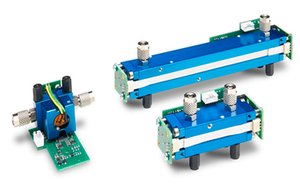

SO2F2 sensors from smartGAS assure safety!

Containers with timber or other products are gassed with odourless and colourless sulfuryl fluoride (SO2F2) or methyl bromide (CH3Br) prior to transport in order to prevent damage to the goods by insects. We have developed our SO2F2 and CH3Br sensors so that users can precisely dose and detect the gassing agent. Like all of our sensors, it works based on infrared adsorption (NDIR) and offers decisive advantages over conventional measuring sensors:

This includes

- an extremely small measuring range of 0 to 100 ppm for personal safety

- high detection ranges up to Vol.-% for initial gassing

- minimum cross-sensitivities to other gases

- high long-term stability in comparison with conventional measuring sensors (IR dual-beam process)

- minimum maintenance

Safely verify gassing agents

Our SO2F2 and CH3Br sensors are an important tool for safely and precisely detecting gassing agents in the environmental air, because they

- help you select the correct dose of the gas

- warn personnel in good time of harmful SO2F2 concentrations

- provide reliable verification of toxic gases in import containers

Important contribution to occupational safety

Our SO2F2 and CH3Br sensors also make an important contribution to the safety of your employees for container gassing and/or handling of gassed containers. In order to optimally integrate the measuring sensor into your application, we work with you to produce a variety of analogue and digital standard interfaces based on our FLOWEVO platform.